Our products comply

with the highest international

standards and guidelines.

CHEMA-GmbH has

internationally

valid

certificates.

Vessels and Reactors

Technologically sophisticated devices plant engineering for the chemical industry, food industry, pharmacy and environmental technologies

The focus of CHEMA’s production is the production of technologically sophisticated, pressurized agitator vessels incl. agitator, reactors, fermenters and process devices.

The design of the vessels is based – according to the individual customer’s request – e.g. according to AD instruction sheets, ASME Code, EN 13445, China Code and other certified design regulations.

In many chemical and biological processes, the precision of the heat supply and heat removal determines the time efficiency of the processes and the quality of the final products.

CHEMA Prozess- und Systemtechnik GmbH manufactures vessels for the heat transfer with heat transfer systems on the outside and/or on the inside.

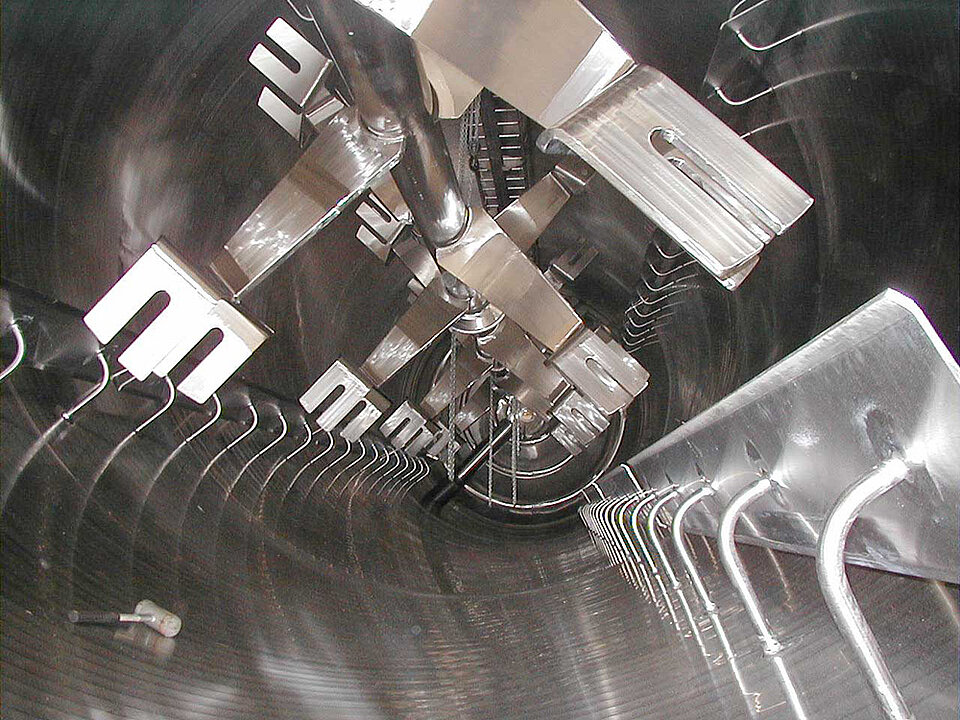

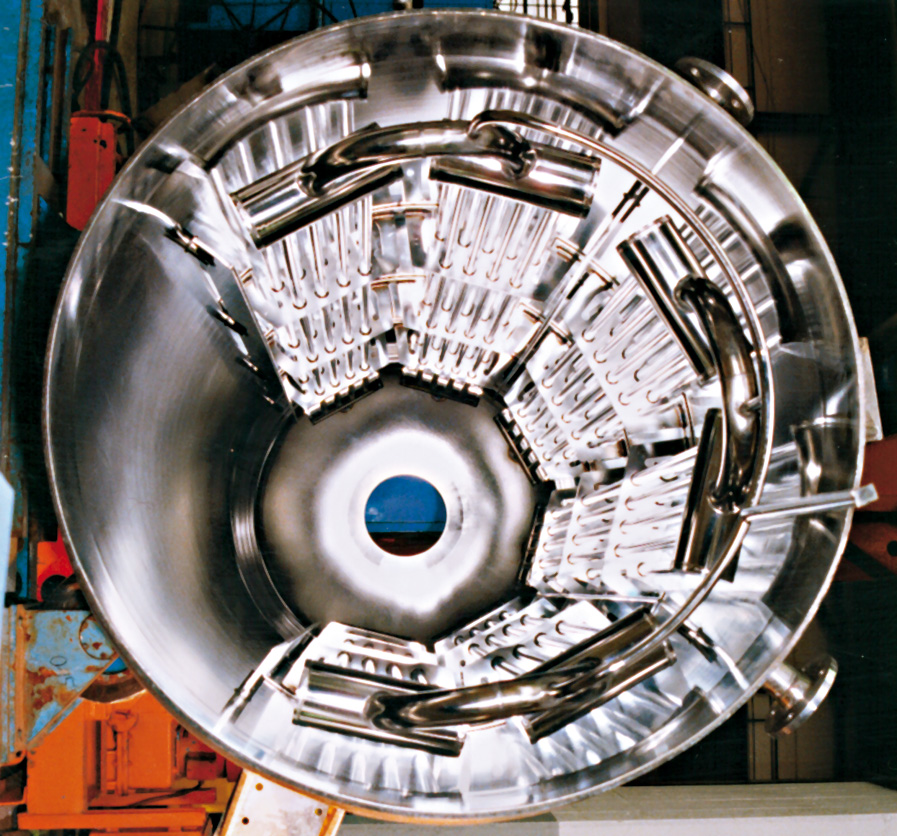

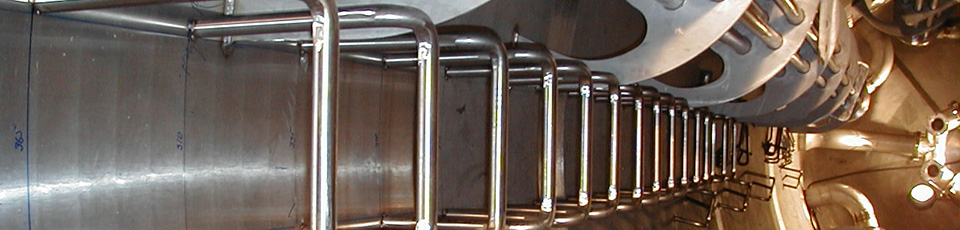

Examples for heat exchangers on the inside are e.g. vertical tube registers, every kind of tube coil systems, spiral tubes and individual heating registers according to the customer’s wishes.

Heat exchangers on the outside might be double jacket– with or without welded-in guide plates – pillow plates or welded half-coil pipes of the most diverse profiles. Depending on the size of the vessel, the welding is done by automat or by hand.